Schelling Process Engineering GmbH was founded by Thomas Schelling. He has a diploma in mechanical engineering with training in process engineering, which corresponds to a Master of Science ETH. Working in various companies from research to engineering to project and product management, Thomas has many years of experience in solving process engineering tasks as a whole.

Tasks for which there are no established standard solutions are particularly interesting. The focus here is on simple, energy-optimised solutions with high-quality components that are easy to operate and maintain in order to achieve optimum cost-effectiveness in the long term.

“On a given day, a given circumstance, you think you have a limit. And you then go for this limit and you touch this limit, and you think, ‚Okay, this is the limit‘. And so you touch this limit, something happens and you suddenly can go a little bit further. With your mind power, your determination, your instinct, and the experience as well, you can fly very high.”

Ayrton Senna

The Katadyn Group manufactures products for outdoor, travel and caravanning as well as mobile desalination plants for boats, yachts and land-based facilities.

As product manager and development engineer Thomas was responsible for the portable water filters and small dewatering systems as well as for second and third-level support of these products.

At the same time the new production building was built and Thomas was involved in the commissioning of the new kiln with upstream drying of the ceramic filters as well as the commissioning of the new plant for the production of folded filter media. In the field of desalinators, Thomas has developed a conversion kit with which the drive can be easily repaired on the way.

Mecan Ecosystems has produced compact biodiesel plants. The focus was on the recycling of used deep-frying oil and waste fats from slaughterhouses or even from agricultural companies that want to produce their own fuel for their own use.

In addition to improving the existing systems, Thomas has also developed a continuous laboratory-scale system that has made the process even simpler and more compact. Due to the increasing lack of acceptance of biodiesel, regardless of the origin of the raw materials and the general accusation of food competition, the plant was not further developed.

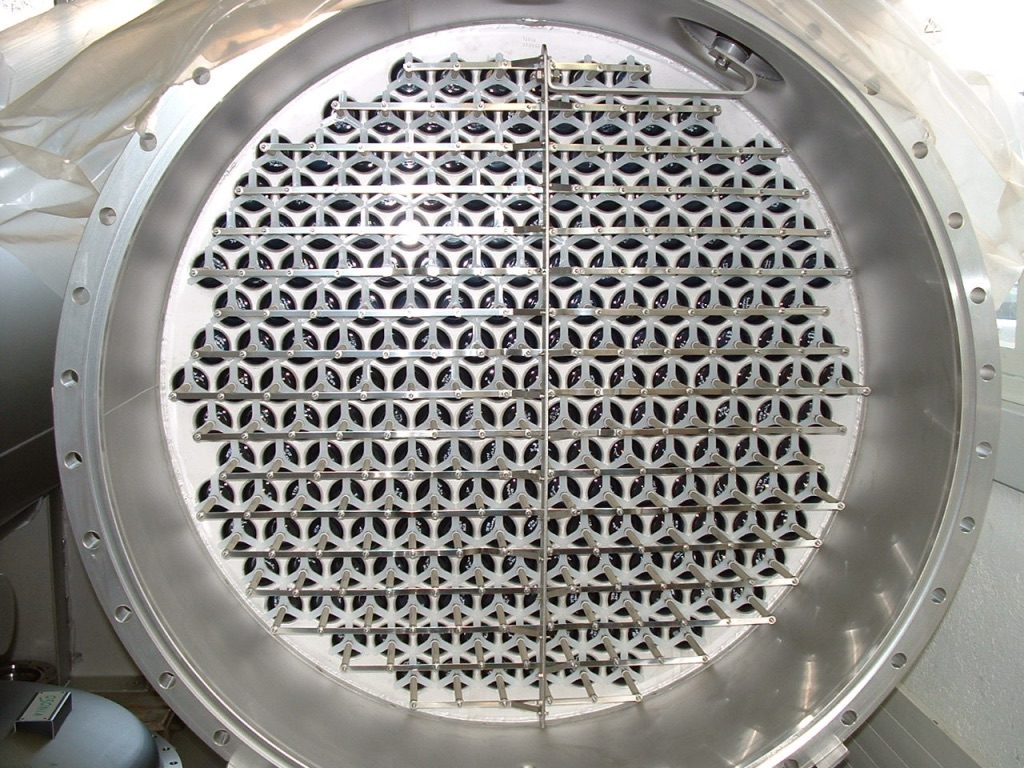

Ozone is a strong oxidizing agent that is used for disinfection and removal of iron, manganese and flavourings in water treatment. In pulp bleaching (paper production) it is used in addition to hydrogen peroxide for bleaching in the chlorine-free process.

Thomas worked as a process engineer. His work included the creation of the flow diagrams, specification of the plant components, coordination and supervision of the installation planning up to erection supervision and commissioning.

In the High Temperature Solar Chemistry group, Thomas was involved in the development and testing of powder cloud reactors with integrated heat recovery. The powder clouds of metal oxides are exposed to highly contrasted solar radiation and temperatures of over 2000 K are reached in the center to reduce the metal oxides and chemically store the heat.

In addition to the reduction of metal oxides, calcination in such reactors was also investigated. It was shown that solar-assisted calcination of raw cement powder could significantly reduce the use of fossil fuels in cement production. After initial great interest from industry, it was unfortunately not possible to raise sufficient final funds for a corresponding project.